E3.infinite – Revolutionizing the E/E Design Industry

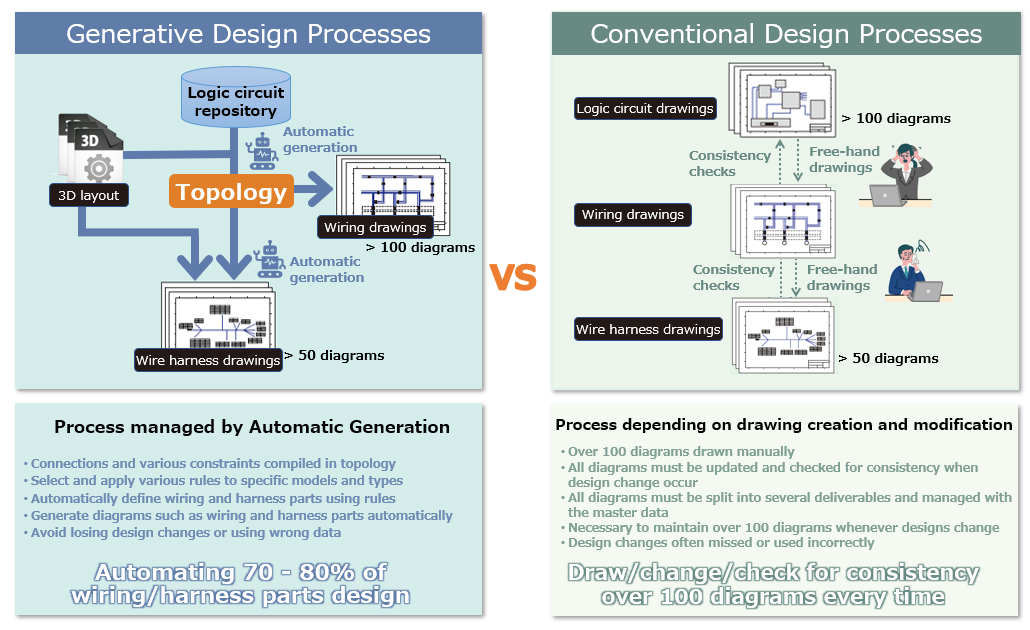

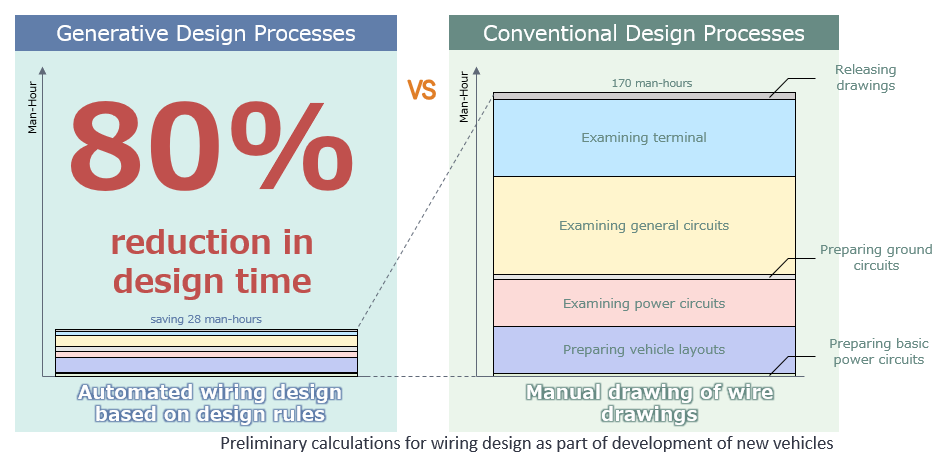

The field of electronic and electrical (E/E) design is experiencing a paradigm shift with the emergence of generative design processes. Unlike conventional design processes, generative design harnesses the power of artificial intelligence, algorithms, and rule sets to create optimized designs based on predefined constraints and objectives. This innovative approach offers significant benefits in terms of design efficiency, quality, and adaptability.